Monitoring for Particle Contamination in High-Purity Process Chemicals

(On-demand Webinar)

Monitoring for particle contamination in high-purity process chemicals results in improved yield.

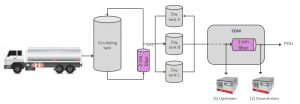

The critical dimension of today’s advanced semiconductors continues to trend to smaller sizes. Killer particles have been shown to come from many sources at these small geometries. It is no longer enough to rely on the Certificates of Analysis (CoA) from high-purity material manufacturers, and in particular, for bulk and specialty chemical suppliers. Continuous particle monitoring of chemicals at all stages of the chemical distribution process is required to maintain the ultra-cleanliness that is required for control.

Attend to Learn

- Effects of transportation on chemical cleanliness

- Protection of the manufacturing process through filtration

- Time to usability for new liquid filters

- Effects of liquid filter aging on the process

- Options for Point-of-Use (PoU) process tool chemical particle monitoring

Complete the form to access the full webinar – Download now, listen when you are ready

Ready to get started with your particle counting solutions? Particle Measuring Systems has a variety of options depending on your application:

- 20 nm monitoring with the SLS 20 sampler and Chem 20 chemical particle counter

- Available in a variety of configurations