In discussing acceptable particle losses in tubing, there are many factors. Transportation of particles in tubing between a sample inlet and the optics of particle counters has at many times been at the forefront of discussion regarding the truth of readings. When the validation implications of losses due to various forces are reviewed, the certainty of the result is always in question. So, what are these forces, what are the losses, and what are the acceptable results? This paper addresses these issues to allow for a better understanding of the problem. Learn about forces and mechanisms acting on particles including:

- the Stokes number

- drag coefficient

- relaxation time

- deposition velocity

- Viscous force

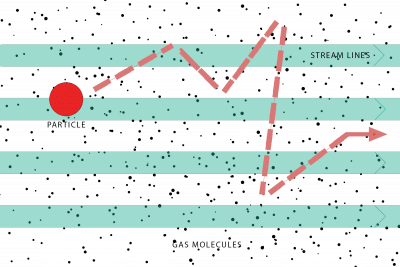

- Brownian motion

- Gravitational force

- Electrostatic forces

- Diffusion forces

- Thermophoretic forces

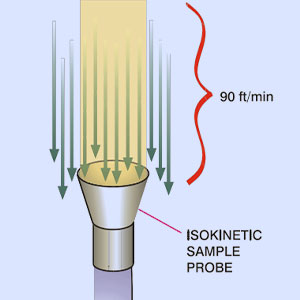

Isokinetic Sampling

In laminar flow environments, or in ducts leading to a filter, the air is considered to be moving unidirectionally. The sampling of this air flow must neither be over or under the distribution of particles within that flow. This requirement is satisfied when isokinetic sampling is performed. Isokinetic sampling means that the air velocity in the supply air is the same as the air velocity in the particle counter’s sample-tubing inlet.

If the velocities differ, then either a positive or negative sample collection error occurs. An isokinetic sample error increases with particle size, but is not of great concern for particles smaller than 1–2 μm. Federal Standard FS 209E1 shows that isokinetic sampling errors greater than 5% are not expected for particles smaller than a few micrometers when using a sample probe with inlet diameter of 2 mm or larger, even when sampling and sampled air velocities differ by an order of magnitude. However, when macro particles > 5 μm are to be measured, then isokinetic sampling is required. Particle Measuring Systems has a calculator that accurately assesses the dimensions of the isokinetic probe and the associated errors should a non-standard sample probe be used.

Learn more… Complete the form to download the full paper.

Get the experts in Particle Measuring Systems’ Advisory team to do your risk assessment for tubing particle loss.

Particle loss in transport tubing can occur due to a combination of various external factors. To assess the risk and potential impact on the finished product, it is crucial to conduct particle transportation tests. The primary objective of these tests is twofold: first, to quantify the resultant particle losses within a remote sampling system, and second, to provide documented evidence characterizing the efficiency of viable and non-viable monitoring processes. By addressing these aspects, manufacturers can gain valuable insights into the particle transportation dynamics in their remote systems and ensure appropriate measures are taken to maintain product quality.