How do Aerosol Particle Counters Work?

Aerosol particle counter technology enables the rapid count and size of contaminant particles in cleanroom air and other controlled environments. Users tend to see this as a device where a button is pressed, and absolute results tumble out. However, when measuring anything small, it is important to be aware of the technology within the instrument to understand the relevance of the data generated, to put the operation of particle counters in context, and to be aware of its benefits and limitations. No measurement is absolute―all are relative to the measuring technique employed. For example, if we measure particles with a scanning electron microscope, it would not be a surprise to get slightly different results. We might even get vastly different results at certain sizes, because that particular technology is producing a response which differs from that produced by the particle counter.

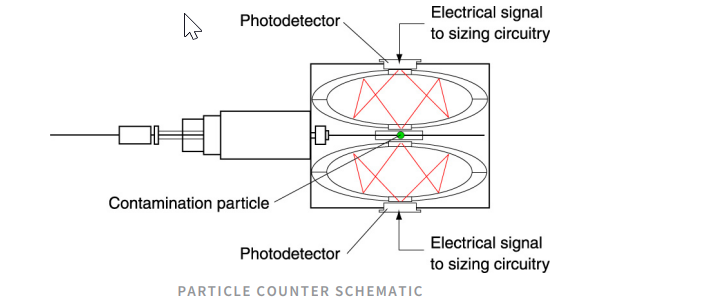

All commonly used cleanroom aerosol particle counters, regardless of their manufacturer, are based on the light scattering principle. Essentially, this means that they use a very bright light source to illuminate the particles. Nowadays this source is a laser diode, where previously gas lasers and ‘white light’ halogen bulbs were used. This very bright light source shines through an optical block. Within the optical block are mirrors and either one or more photodetectors. Sampled air is drawn through the laser beam by a small vacuum pump. As the particles in the air pass through the laser beam, the laser light interacts with particles and is scattered. The term ‘scattering’ means that the light undergoes a directional change. This change occurs in all directions: Forwards, backwards and sideways. Below is a schematic of how a sampled particle is read:

What aerosol particle counters do very well is allow users to take instantaneous samples and get a very good real time indication of the load of particles in a room or around a critical process. Alternative methods, such as using a filter, pump, or microscope, are time consuming, subjective, and labor-intensive. Aerosol particle counters have been and continue to be crucial and beneficial in the development, operation, and advancement of cleanroom production environments. They are fast, well defined, and non-subjective, and modern instruments are now extremely stable, robust, and simple to use. By using the scientific principles of light scattering and comparison to a calibrated reference, these devices ensure repeatable, reliable data.

This paper covers:

- particle types

- particle sizes

- Calibration Reference Standard using Latex Spheres

- aerosol particle counter technology

Complete the form here to get the full paper to understand how aerosol particle counters work.