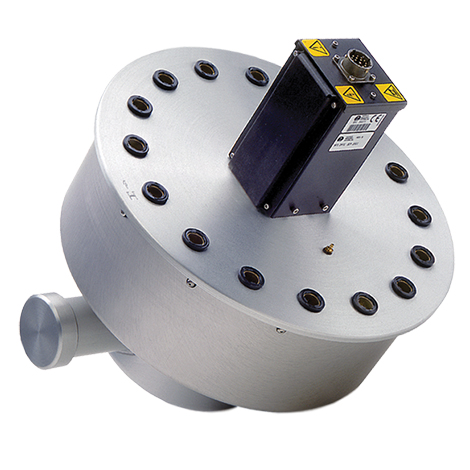

AM ll 16/32: Aerosol Manifold for Sequential Monitoring

Advanced Aerosol Manifold for sequentially monitoring aerosol contamination at multiple cleanroom locations with a fixed airborne particle counter.

The AM II Aerosol Manifold from Particle Measuring Systems offers advanced features for sequentially monitoring contamination at multiple cleanroom locations with a fixed airborne particle counter. The AM II aerosol manifold is ideal for trend analysis and cleanroom verification when continuous monitoring is not needed.

Compatible with all 1.0 CFM Particle Measuring Systems’ Cleanroom Particle Counters:

Product Details

- Multiplexed sequential particle monitoring of up to 32 locations with a single airborne particle counter

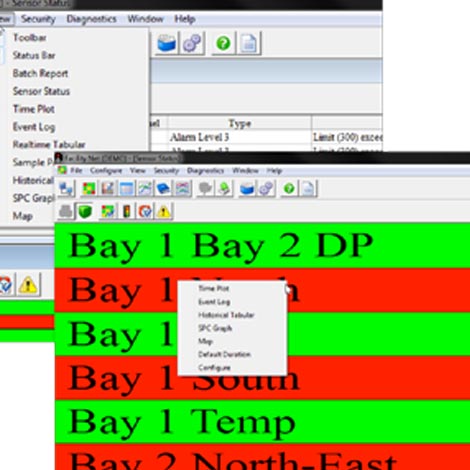

- Controlled by FacilityNet™ or PharmaceuticalNet™ Software

- Programmable recipes and sample point sequences

- Assembly designed to eliminate contamination from valves

- Alarm for low vacuum; automatic shut-off for pump overheating

- Most economical cleanroom monitoring of fixed points at timed intervals

- Low cost per sample location

- Monitors a much larger area than a fixed particle counter

- Ethernet communications to facility monitoring system

- Easily programs a sampling routine, for either simple or complex sequences

- Automatically changes sampling recipe upon receiving alarm or external signal

- Large coverage area: each sample point can be up to 125 ft away

- Patented flow control ensures the aerosol manifold properly compensates for pressure drop, eliminating systematic particle undercounting of up to 15%

- Maintains constant flow (nominal 3 CFM) at each particle counting sample location to minimize gravitational particle setting

- With isokinetic sampling probes, captures particles at the same velocity as sample air, preventing distortion in particle size relationships

- Cleanroom Facility monitoring

- Monitoring large minienvironments

- Cleanroom verification and trend analysis

Resources

Accessories

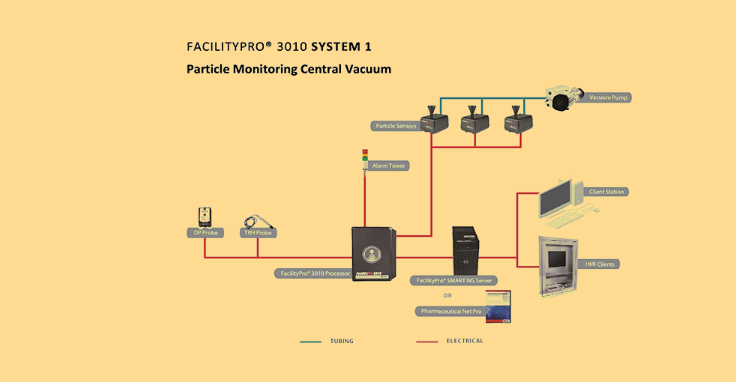

Part of a Facility Monitoring System

Facility Monitoring Systems with industrial controls assure data integrity, process automation, simplicity of use, and data integration.

Learn more

Not sure where to start? Here are the next steps:

Tell us about your application requirements.

Our experts will help you find the right solutions to meet your specific requirements

Once we identify the best solution for you, we provide you with pricing and delivery dates.

Related Products