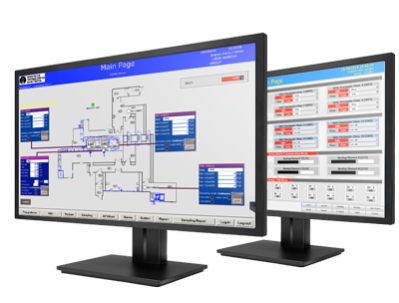

Both Pharmaceutical Net and FacilityPro software provide cleanroom data management from your particle counters, microbial monitors, and other sensors.

The primary reasons you should upgrade to the FacilityPro® Environmental Monitoring System:

- Data Integrity – Ensures accurate, unaltered data collection records

- Design Simplicity – Organizes numerous components (sensors, vacuum lines, clients, etc.) into a straightforward and manageable network for personnel

- Ease of Integration – Facilitates cleanroom protocol and procedure generation

- Automation Improvement – Improved gathering, storing and reporting of data, and remote access expansion via WiFi

Data integrity denotes robust system architecture which ensures data is always reliable and protected when needed for batch release and record retention. Supporting features of data integrity include the industrial approach and architecture design, sensor-driven time stamping, redundant iFix/Historian (SCADA) servers, data buffer, backup and recovery, redundant vacuum control (5010 series), and 21 CFR Part 11 compliance.

The simplicity of the design, which employs a standard modular concept, allows for expedited validation. PLC and SCADA programming are handled in advance with ON/OFF switches for user accessibility and immediate application in an industrial setting. Standard industrial components make it possible for IT groups to manage the system without outside consultancy.

The ease of integration allows for FMS protocols to be written into cleanroom and process procedures.

Automation makes it easier to collect, report and analyze data. In the FacilityPro system, automation is supported by viable, nonviable and environmental controls, sampling automation through recipes, batch identifiers and data filters, and configurable reports and cleanroom data management. Recipes allow sampling to be performed on an automatic-basis, driven by the SOP. The system is designed to manage viable, nonviable and environmental sensors. Microbiological sensors require a start and stop to sampling, whereas particle and environmental sensors are usually sampling continuously. Logic needs to align in order to combine data. Reports can be filtered down for easier cleanroom data management when dealing with a large volume of samples.

Learn more… Get the full paper here.