This paper discusses how to ensure that a liquid optical particle counter (OPC) is producing valid data.

This paper discusses how to ensure that a liquid optical particle counter (OPC) is producing valid data.

Ensuring that your liquid OPC is operating within its designed specification is critical to obtaining quality data. As data from OPCs becomes increasingly important to maintaining process control, it becomes more critical than ever for operators to have confidence in the data being generated. OPC data is frequently used to qualify process improvements, control chemical manufacturing, and maintain quality control for production of complex parts. It is common for operators to wonder if the OPC is working correctly when the data collected does not match their expectations. Common misunderstandings and performance issues about OPCs are discussed to help the operator reach proper conclusions when questions arise about the validity of the data.

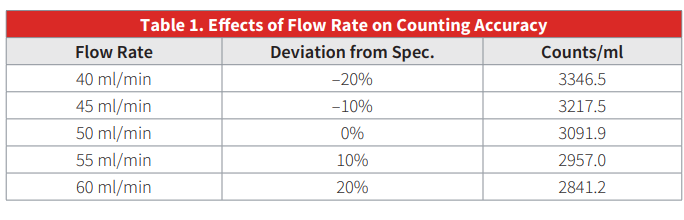

Operators can take several easy steps to ensure that quality data is collected from an OPC. All OPCs have defined and easily-controlled specifications. These specifications are:

- flow rate

- background scatter

- concentration limit

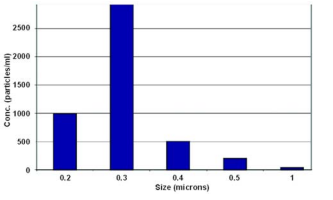

Particle size distribution is also important. Unless all these parameters are correct, the data quality should be considered suspect. These parameters and their effects on each other are discussed below, as well as how to ultimately ensure that quality data is achieved when analyzing ambient particle distributions in process chemicals and DI water.

Complete the form to access the full paper.