Modern manufacturing frequently requires clean environments that are designed, constructed, and sustained to enable the highest yields possible while also hitting predictable throughput targets. This commonly involves achieving a specified cleanroom classification to establish the level of cleanroom performance, and subsequent sustaining efforts that are efficient and nimble. Having the right particle detection equipment for this application is necessary to accomplish these tasks.

Modern manufacturing frequently requires clean environments that are designed, constructed, and sustained to enable the highest yields possible while also hitting predictable throughput targets. This commonly involves achieving a specified cleanroom classification to establish the level of cleanroom performance, and subsequent sustaining efforts that are efficient and nimble. Having the right particle detection equipment for this application is necessary to accomplish these tasks.

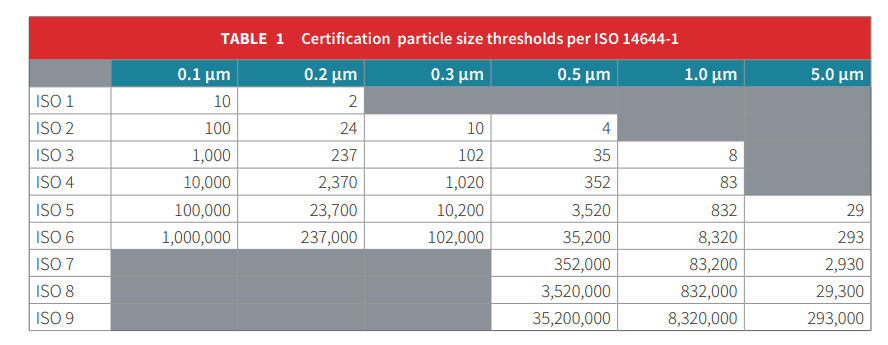

Cleanroom certification requires the use of the most sensitive particle counters during the initial certification phases and are reused again at specific recertification time intervals after that. Certification data collection requires data from prescribed area locations as defined in the certification standards. Sustaining and troubleshooting efforts generally require a customized approach which need not adhere to the prescription of any standard but depend on the experience of the cleanroom owners to determine the areas of interest and optimal data collection frequency.

Tailoring Solutions for an Evolving Industry

Individual cleanroom owners must choose the collection schemes that make the most sense to support factory yield optimization without hindering normal operations of the factory. Collection often includes continuous real-time methods that gather data from sensors in static locations throughout the factory on a 24 /7 basis, which provide valuable snapshots of cleanroom performance as well as insightful trends at those locations over time. However, sustaining and troubleshooting efforts also require more agility than mobile “counter-on-a-cart” configurations and static sensor locations can provide.

The HandiLaz® Mini II handheld particle counter offers a powerful and nimble solution for the following scenarios:

- Pre-certification to quickly establish a baseline of an area’s particle counts and gain preliminary data to support the timing of an actual certification effort.

- Identifying potential hotspots where high particle counts may present challenging issues that should be addressed before more costly certification efforts begin.

- Troubleshooting in high particle areas to support certification and sustainment by providing high spatial-resolution data to precisely locate particle sources.

- Providing appropriate data collection capabilities during ongoing area mapping at planned sustainment intervals.

- Verification that laminar airflow schemes are effectively capturing and eliminating particle counts from propagating to cleaner areas.

This paper highlights some of the many applications across various industrial sectors, including Semiconductor Fab (ISO 1 through ISO 5), clean manufacturing (> ISO 5), Process Tool OEM, Automotive and Aerospace, LED/LCD, Materials, Medical, and Pharmaceutical Manufacturing. Across these segments, the HandiLaz Mini II particle counter’s features enhance the capabilities of cleanroom control personnel at all stages of cleanroom control, including certification and sustaining, excursion response with pinpoint accuracy, filter and parts testing, and overall manufacturing readiness. Together with the high sensitivity and versatile, easy deployment, the HandiLaz Mini II can be used dynamically to increase efficiencies and yields, which translate directly to bottom-line results and personnel empowerment.