Understanding and preventing Particle Loss in Tubing can have notable results in contamination control.

Particle counters are used in many applications ranging from cleanroom and clean air device classification in accordance with specified standards, testing of filter installation, portable environmental monitoring programs, in-situ environmental monitoring systems, and the fault diagnosis of specific processes. Historically, there has been a single volume flow rate of 1 CFM (28.3 LPM) chosen for many of these applications.

Particle counters are used in many applications ranging from cleanroom and clean air device classification in accordance with specified standards, testing of filter installation, portable environmental monitoring programs, in-situ environmental monitoring systems, and the fault diagnosis of specific processes. Historically, there has been a single volume flow rate of 1 CFM (28.3 LPM) chosen for many of these applications.

Manufacturers of particle counters found that as regulations changed, higher volume flow rates were preferred for the classification of cleanrooms to either ISO14644-1 or EU GMP Annex 1 standards. However, the requirement for monitoring a process using a ‘standard’ 1 CFM device continues to be the most suitable method of acquiring data at an ideal rate with the confidence that the process can be economically measured.

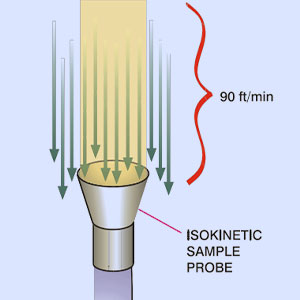

As there are different types of instruments available, each with a different flow rate, a concern arises in the industry of what constitutes suitable transit of particles within tubing. Particle Measuring Systems has previously released information regarding the maximum suitable length of transport tubing, and this has been reinforced by the release of ISO 14644-1:2015 which advocates for shorter tubing lengths, World Health Organization requirements for vaccine manufacture which recommends that no more than 2.0 meters of tubing should be used, and the upcoming release of the updated EU GMP Annex 1, which discusses particle counter applications.

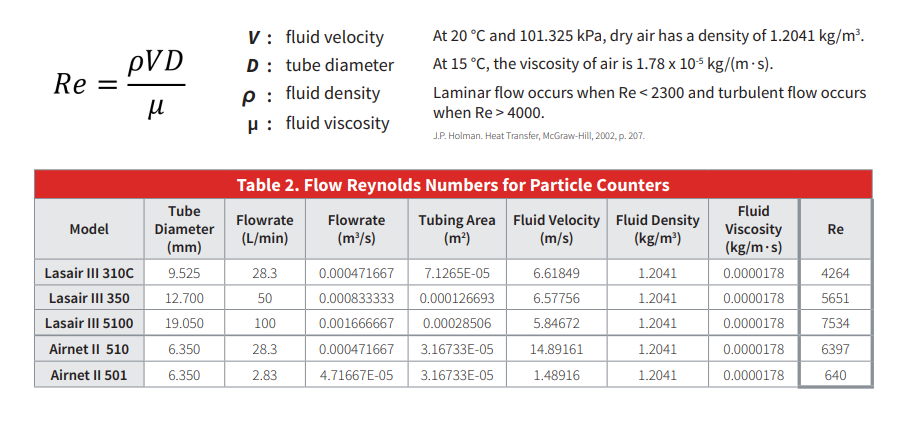

There are several factors affecting particle loss in transport tubing, and these have been discussed in An Analysis of Acceptable Particle Losses in Transport Tubing. A function of these factors is to ensure that turbulent flow is maintained, thus ensuring that particles are transported with maximum efficiency. The Reynolds number (Re) is a function of turbulence and it is widely recognized that turbulent flow exists where Re is greater than 40005.

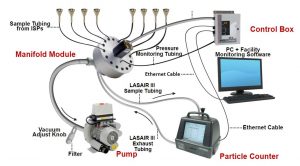

Re was calculated for each of the three Lasair III counters under review as well as two, fixed location Airnet II particle sensors. It can be seen in Table 2 that turbulent flow exists in the transport tubing to the Lasair III particle counter, irrespective of the flow rate chosen. This verifies that the losses due to particle transport are minimized. However, it does not mitigate all losses, and further testing is required to demonstrate empirically what those losses …

Complete the form to download the full paper…

Get the experts in Particle Measuring Systems’ Advisory team to do your risk assessment for tubing particle loss.

Particle loss in transport tubing can occur due to a combination of various external factors. To assess the risk and potential impact on the finished product, it is crucial to conduct particle transportation tests. The primary objective of these tests is twofold: first, to quantify the resultant particle losses within a remote sampling system, and second, to provide documented evidence characterizing the efficiency of viable and non-viable monitoring processes. By addressing these aspects, manufacturers can gain valuable insights into the particle transportation dynamics in their remote systems and ensure appropriate measures are taken to maintain product quality.