Who Defines Your Contamination Control Strategy?

Did you define your manufacturing contamination control strategy, or is it a collection of changes over time?

At Particle Measuring Systems we have the experts to support you at every step in your contamination control process. Whether it be non-compliance issues, setting up a new process, or training employees, our team has the background, education, and industry expertise you need. Our ongoing dialogue with worldwide regulatory agencies ensures you are on the cutting edge of the latest requirements, and we have the knowledge and background to support you at all stages of your operation. Whatever your contamination control hurdle is, you can trust that the experts at PMS have seen it and are equipped to remedy the problem for good, setting your operations on a path to success.

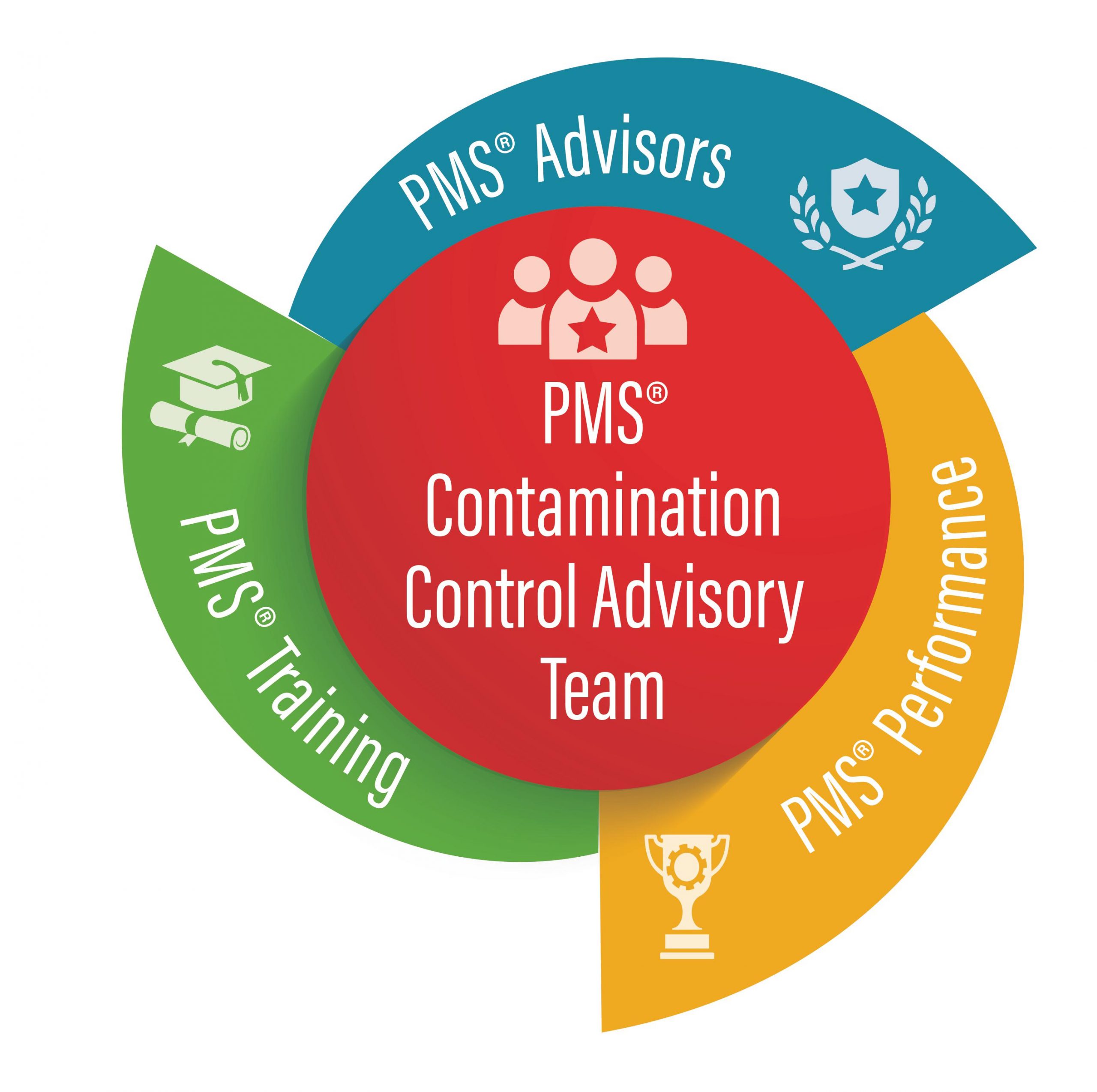

Our Advisory Services Solutions

PMS® Advisory Services

Helping you to achieve the highest level of contamination control and sterility assurance.

Learn more >

PMS® Training

Preparing your employees to ensure success at every step.

Learn more >

PMS® Performance Optimization

Designing quality into your operation using gold-standard PMS tools & processes.

Learn more >