In the highly regulated and risk-sensitive world of pharmaceutical manufacturing, adherence to stringent compliance measures is paramount. To achieve this, pharmaceutical companies use controlled environments, particularly cleanrooms, where the risk of variability and particle contamination is minimized. Here we’ll delve into the significance of cleanrooms and explore a key contamination management technique employed within them—Isokinetic Sampling and unidirectional airflow.

The Essence of Cleanrooms

Cleanrooms are specialized spaces designed to maintain strict control over air quality, ensuring that air filtration, distribution, utilities, materials of construction, and equipment are all managed in a controlled manner. The primary goal is to create an environment where the risk of contamination is significantly reduced, aligning with regulatory standards and ensuring the production of safe and high-quality pharmaceutical products.

The Power of Unidirectional Airflow

At the heart of cleanroom design is the concept of unidirectional airflow—a technique that employs a controlled, steady velocity of air moving in parallel streamlines in one direction. This method minimizes the potential movement of particle contamination within the cleanroom environment. Unidirectional cleanrooms typically incorporate laminar airflow hoods to direct the air effectively. The strategic design ensures that the airflow washes particles away from potential contamination sources, preventing them from reaching critical processes.

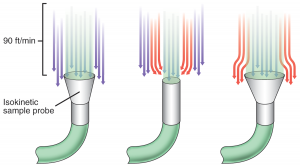

Unveiling Isokinetic Particle Sampling

A crucial aspect of maintaining the integrity of unidirectional airflow is the use of isokinetic particle sampling. This technique allows for an accurate collection of particles entrained within the air flow without disrupting the carefully designed airflow patterns. The optimum air flow rate for isokinetic particle sampling is historically defined as 90 feet per minute, approximately equivalent to 0.45 m/s. This specific flow rate acts as a sheathing air, effectively washing particles away from potential contamination sources before being exhausted from the cleanroom.

The Science Behind Isokinetic Sampling

To gain a deeper understanding of isokinetic particle sampling and its role in preserving cleanroom integrity, one can explore the principles outlined in a comprehensive paper on the subject. The paper provides insights into the science behind isokinetic sampling, emphasizing its importance in achieving accurate and reliable results in particle analysis within controlled environments.