In our previous blog on how particle counters work, we looked at the physicality of what particle counters measure and the importance of calibration. In this final installment, we look at the technology behind the results. How does a particle make it from sampled air into a number on your data screen?

Particle Counter Light Source

All commonly used cleanroom airborne particle counters, regardless of manufacturer, are based on the light scattering principle. This means they use a very bright light source to illuminate the particles. Nowadays this source is a laser diode, but in the past there were gas lasers and ‘white light’ halogen bulbs.

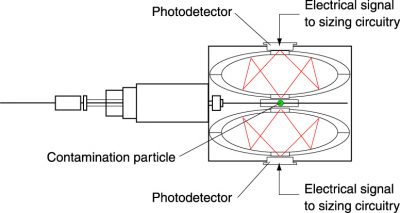

The bright light shines through an optical block, made of mirrors and photodetectors. Sampled air funnels to where the laser beam can pass through it by a small vacuum pump. The laser interacts with particles and light is scattered as a result. By scattering, we mean light changes direction every which way. See below.

Particle Counter Mirrors

The elliptical clam shapes in the diagram are mirrors. In a particle counter, the mirrors are silvered so the reflecting surface is inside. The light scatters and hits the mirrors, which focus the scattered light onto one or more photodetectors.

Particle Counter Photodetectors

The photodetector converts the burst of light energy from each particle into a pulse of electrical energy. By measuring the height of the signal and referencing it to the calibration curve we get the size of the particle. By counting the number of pulses, we can determine quantity. Particle numbers assimilate into size channels.

The Science of Light Scattering

Light scattering is a general term and is composed of various different physical phenomena. Scattering is made up of:

- Reflected light – Particles angularly deflect the light

- Refracted light – Light shines through the particle, which changes the direction of the beam

- Diffracted light – Light bends around the particles it passes near

Also note there may also be a degree of absorption when a percentage of the light energy is retained by the particle. In some instances, effects such as phosphorescence may occur from some particles types. Therefore, scattering is a combination of many physical properties relating to light, and the interaction of light and particles. This interaction depends on the particle composition, its refractive index, and the difference between that particle and the background medium, (i.e., air).

Particle Counter Calibration and Sizing Accuracy

In operation, the instrument compares the response it is getting from the particle signal to the calibration curve generated with latex spheres. What the instrument is actually doing is comparing the response from the interaction of that particle and the laser light and then relating it to the ideal latex sphere in a background medium of air. Be aware that particles with different scattering responses will size either smaller or larger relative to the latex standard.

For example, a silicon particle has a high reflectivity relative to the latex standard, and is going to scatter a great deal of light. A particle of this material will size large compared to the standard. A particle that absorbs light or doesn’t scatter very much light is going to size small relative to the latex standard. So what does this mean? Well, it means we are not dealing in absolutes. These sizing differences from the latex standard may assign the particles into larger or smaller size channels.

The particle’s orientation while passing through the laser beam affects its sizing. An extreme example is a rod shaped particle exposing its full length to the laser beam. The light strikes the largest surface area and scatters a relatively large amount of light. If the rod only exposed one of its ends, its relatively smaller cross sectional area would cause it to size as a small particle.

Bringing It All Together

What particle counters do very well is allow users to take instantaneous samples and get a very good real-time indication of the load of particles in a room or around a critical process. Alternative methods, such as using a filter, pump, or microscope, are time consuming, subjective, and labor-intensive.

Aerosol particle counters have been and continue to be crucial and beneficial in the development, operation, and advancement of cleanroom production environments. They are fast, well defined, and non-subjective, and modern instruments are now extremely stable, robust, and simple to use. By using the scientific principles of light scattering and comparison to a calibrated reference, these devices ensure repeatable, reliable data.

Learn more… Download the full paper here.