Solution using the Using the Airnet® II Air Particle Counter

Aerosol Particle Monitoring with the semiconductor industry helps prevent damaging contamination by alerting when initial contamination is identified.

The semiconductor manufacturing process involves a series of process steps including, but not limited to, film deposition, photolithography, etching, and chemical mechanical polishing (CMP) processes. Contamination can significantly impact the manufacturing yield, resulting in revenue loss; contamination monitoring and control are critical. Particles are one of the most common types of contamination during integrated circuit (IC) fabrication. Real-time, continuous particle monitoring enables the manufacturer to find particle events as they happen and can help identify the source of the contamination to contain it and minimize the impact.

For two semiconductor manufacturing applications, Particle Measuring System’s Airnet II 201-4 portable aerosol particle counter was the perfect solution to a complicated manufacturing problem. The instrument allowed manufacturers to understand and reduce their particle contamination in critical ways. Along with discussing these case studies, the technical challenges and suggestions for particle monitoring in semiconductor process tools will also be discussed in this paper.

Current particle monitor methodology

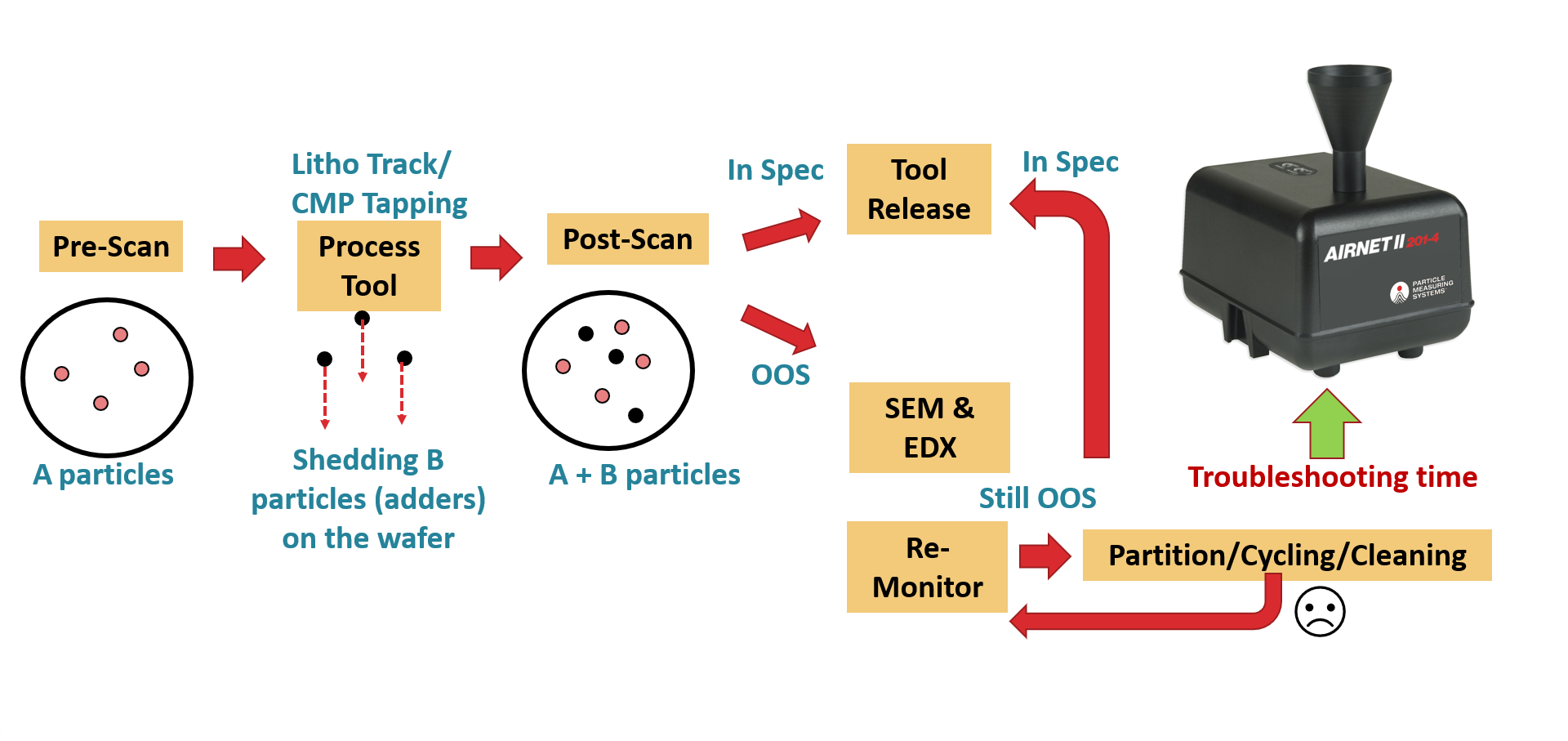

Particles are one of the major causes of yield loss during the IC manufacturing process. Most IC manufacturers use inspection tools to scan the particles on control wafers. This methodology involves running the control wafers through the simulated processes. The control wafers are scanned before and after the process to calculate the particle count deposition difference between scans, aka the adder count. If the particle adder count is out of spec (OOS), the process tool must be cleaned and serviced to eliminate the particle sources until it passes the particle spec, as illustrated in the figure below.

Historical constraints of using inline particle counter for monitoring process tools

- Limited sample flow rate:

The mini-environments or chambers of most process tools maintain a positive pressure to keep external contaminants (particles) from entering the tool and contaminating the wafers. Most tools use a differential pressure gauge to monitor the positive pressure. To consistently maintain the positive pressure within specification, the sample flow rate of an inline aerosol particle counter must be high enough to provide sufficient flow for particle detection but low enough to not interfere with the positive pressure of the process tools.

- Limited space inside the process tool for installing the particle counter:

The space inside the process tools is constrained due to many components: moving and fixed parts like robots, stages, transfer systems, cables, pipes, etc. The aerosol particle counter must be small enough to fit inside the tool without interfering with the tool’s function/process.

- The constraint of putting the foreign object inside the process tools:

Even if there is enough space to put an aerosol particle counter inside a process tool, the counter can be considered a foreign object that may need to be qualified before being put into the tool. The reason is to ensure that the foreign object is fully compatible with the operation of the process tools. For example, the mechanical properties of the foreign object must be stable to not shed any contaminants and must not obstruct the moving parts. It is also not allowed to create other signals that may jam other process sensors.