Planning and Installing an Environmental Monitoring System

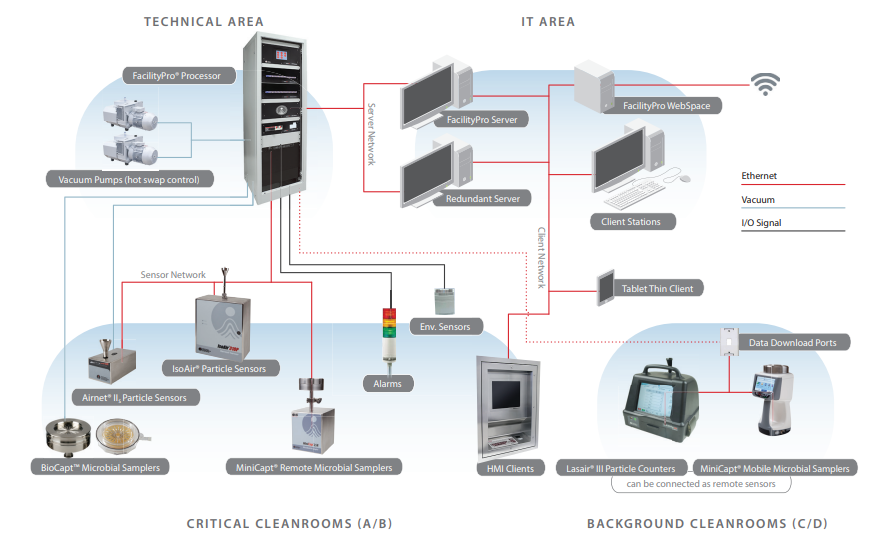

For aseptic manufacture of pharmaceutical products there has been a shift in procedures for particle measurement, primarily due to legislative regulations. Traditionally, monitoring has been the classic portable monitoring of a cleanroom. New regulations have led to a requirement for an automated, remote monitoring solution. This paper reviews the various steps for the implementation of an automated monitoring solution for a non-viable particle counting system. The steps also apply if you later enhance the nonviable-particle counting system to include a viable-particle monitoring or other environmental parameter component.

The key to a successful project is to ensure that all phases of the implementation are executed in a timely manner. The identification of each of the major steps can be presented as a GANTT chart, which will also identify when obstacles, such as shut downs, need to be accommodated. Figure 2 shows a typical timeline GANTT chart for a complete project. Each of these summary tasks can be broken down into individual tasks so that resources, both material and labor, are available. This becomes more critical when multiple components of a project are encroaching on each other. This often occurs during installation when different trades are vying for the same space and during validation when deadlines are tight.

Complete the form to access the full paper.