Airborne Particle Measurements: 100 LPM vs. 1 CFM

Many current standards define airborne particle monitoring in units of particles-per-cubic-meter (particles/m3). Often, these standards require sampling an entire cubic meter (1 m3) to provide an accurate measurement of airborne particulate levels. Using a conventional aerosol particle counter that samples 1-cubic-foot per minute (1 CFM) requires more than 35 minutes to sample 1 m3. Newer particle counters are now available with 100 liter-per-minute (100 LPM) sampling rates. This application note discusses the benefits of sampling at higher flow rates.

Many current standards define airborne particle monitoring in units of particles-per-cubic-meter (particles/m3). Often, these standards require sampling an entire cubic meter (1 m3) to provide an accurate measurement of airborne particulate levels. Using a conventional aerosol particle counter that samples 1-cubic-foot per minute (1 CFM) requires more than 35 minutes to sample 1 m3. Newer particle counters are now available with 100 liter-per-minute (100 LPM) sampling rates. This application note discusses the benefits of sampling at higher flow rates.

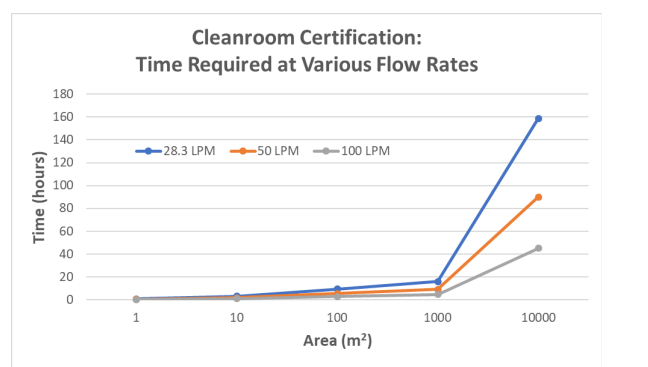

A primary benefit of sampling at higher flowrates is the reduced amount of time required to certify a cleanroom environment (illustrated in Figure 2). When the cleanroom area is very large more sampling locations are required, which causes an exponential rise in sampling time. Subsequently, some procedural standards may require sampling a full cubic meter of air and so using a particle counter with higher sampling flowrates will meet those standards more quickly.

The most common cleanroom standard ISO 14644-1 defines the contamination limits in terms of particles/m3. If a specific test requires sampling an entire cubic meter of air, the test will require 35.3 minutes at flowrates of 28.3 LPM, 20 minutes at flowrates of 50 LPM, and only 10 minutes at flowrates of 100 LPM.

Complete the form to access the full paper.