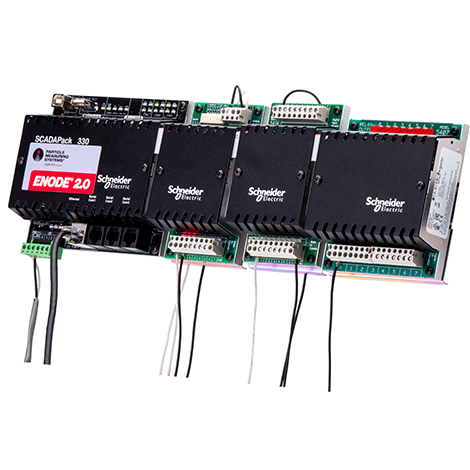

ENODE® 2.0 Distributed I/O Controller

Modular and customizable high-accuracy system control

The ENODE® 2.0 controller is an open architecture,

modular Ethernet device that combines proven

Schneider SCADAPack technology with Particle

Measuring Systems firmware and environmental

monitoring know-how. It can be integrated directly

into Facility Net software to monitor isolated digital

and analog inputs and drive alarm output contacts

(digital or relay).

Particle Measuring Systems engineers, manufactures, installs, calibrates, repairs, and maintains the ENODE® 2.0 controller.

Product Details

- Modular I/O components allow for flexible system designs

- Ethernet 10BaseT/100BaseT connectivity to local networks

- Data buffer stores samples when connection to software is interrupted

- Up to 20 input/output modules connected to one processor

- 8 analog channels per module; 4-20 mA and 0-5 V signal compatible with an overall accuracy of 0.2%

- 16 digital input channels per module

- 8 relay output contacts per module

- 32 digital outputs per module

- Certifications: UL, CE, ATEX II 3G

Cost Effective

- Modular design allows for a mixture of up to 128 signal inputs and/or 128 relay outputs per monitoring device, reducing cost per point

- Sample interval is configured per channel, reducing the number of modules required for different applications

- 4-20 mA and 0-5 V analog input types are configured per channel, not per module, also reducing the number of modules

Easy to Use

- Plug and play modules allow for ease of system expansion

- Module recognition through Facility Net software speeds up system configuration

- DIN rail mounting and removable screw terminals allow for simple installation

- Distributed architecture allows for modules to be installed anywhere throughout the facility

Superior Performance

- High accuracy, 12-bit analog converter gives 0.2% full scale overall accuracy

- 100,000 sample data buffer stores data when offline from software; data is exported to the database on reconnection

- Reliable TCP/IP Ethernet data transmission

- One-second sample interval for fast data-logging

Environmental monitoring and control

- Differential pressure, temperature, humidity, air velocity, and other sensor signals

- Alarm lamp or traffic light control

- Flashing modes

Process monitoring and control

- Doors and switches monitored at each stage of the process

Networked data-logging

Remote data acquisition

Resources

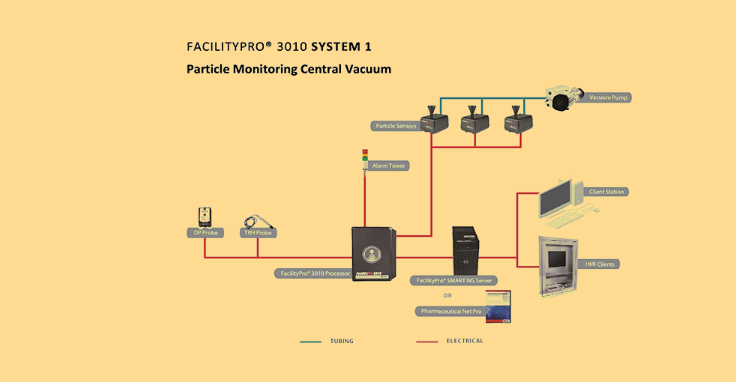

Part of a Facility Monitoring System

Facility Monitoring Systems with industrial controls assure data integrity, process automation, simplicity of use, and data integration.

Learn More

Not sure where to start? Here are the next steps:

Tell us about your application requirements.

Our experts will help you find the right solutions to meet your specific requirements

Once we identify the best solution for you, we provide you with pricing and delivery dates.

Related Products