Normal Particle Size Distributions

It is essential to verify that particle data from the OPC has a normal distribution. If it does not, this should immediately alert the operator to a potential problem.

The following things can lead to abnormal distributions or poor data:

- incorrect flow rate

- excessive background scatter

- exceeding the OPCs upper concentration limit

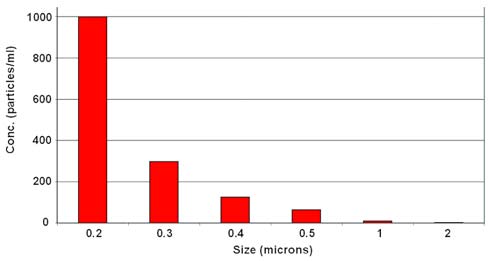

Thirty years of particle counting experience shows that most ambient particle distributions in continuously filtered liquid systems follow a D-3 distribution (D = diameter) on total cumulative counts. Figure 1 shows a normal particle size distribution. Extremely clean DI water systems may have a steeper distribution (D-4). Dirty systems, may have a flatter distribution (D-2). It is equally important that whatever the distribution is, it remains consistent from sample to sample.

Figure 1 Normal particle size distribution, D-3

Also, real particle events such as pump or valve failures, O-ring problems, damaged tubing, or other process upsets can cause abnormal particle distributions. This is why it is critical to ensure that quality OPC data is collected. Otherwise, one would be unable to identify a real particle excursion from a poorly performing OPC.