This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Your Definitive, Modular, and Turn-key Solution for Cleanroom Environmental Contamination Monitoring

Pharmaceutical Environmental Monitoring Systems to monitor your viable and non-viable particles according to the most recent regulatory requirements. Count, report, document and manage your environmental monitoring data meeting 21 CFR Part 11 data integrity requirements.

Unique modular design allows for quick, easy & scalable installation

The robust and flexible system architecture from Particle Measuring Systems (PMS) ensures cleanroom environmental monitoring data is protected and available whenever there is a need for product release and reporting. Solutions for all cleanroom sizes and classes to fit most budgets.

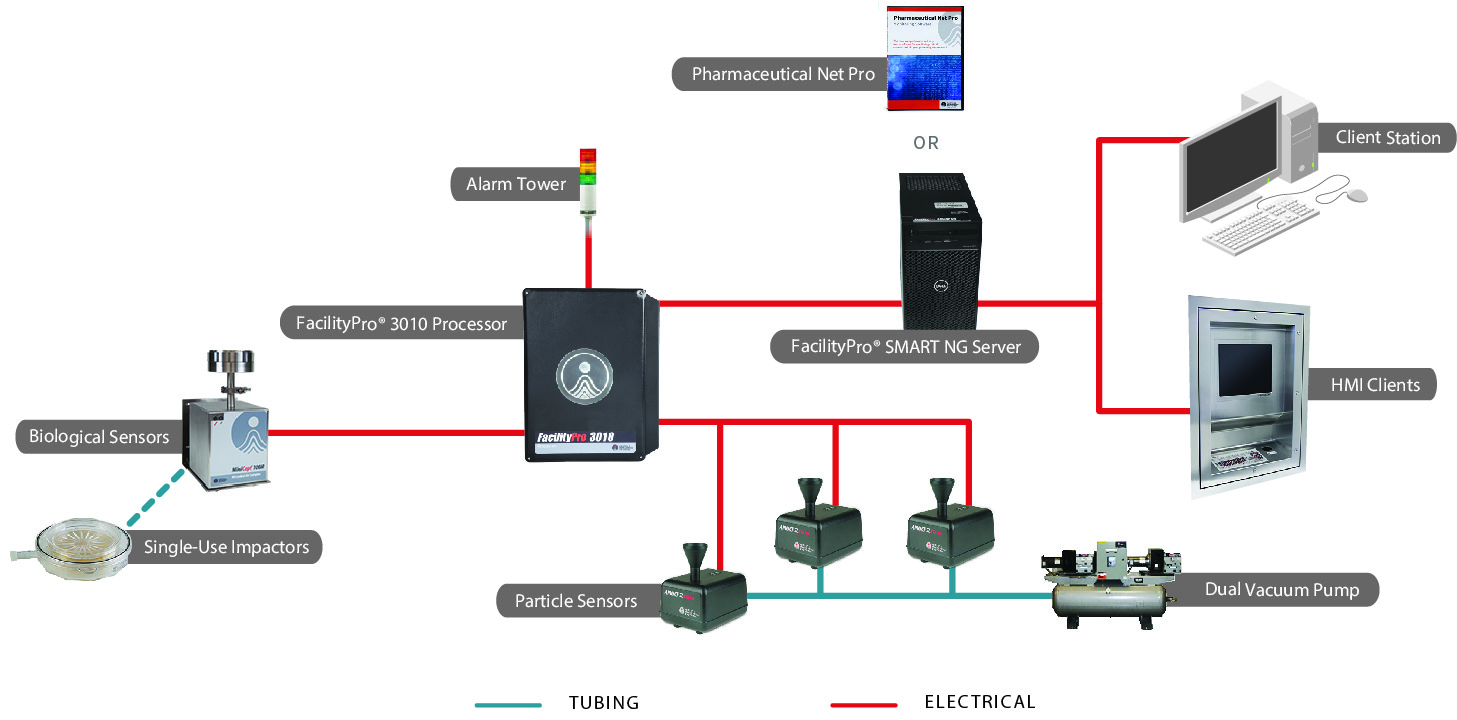

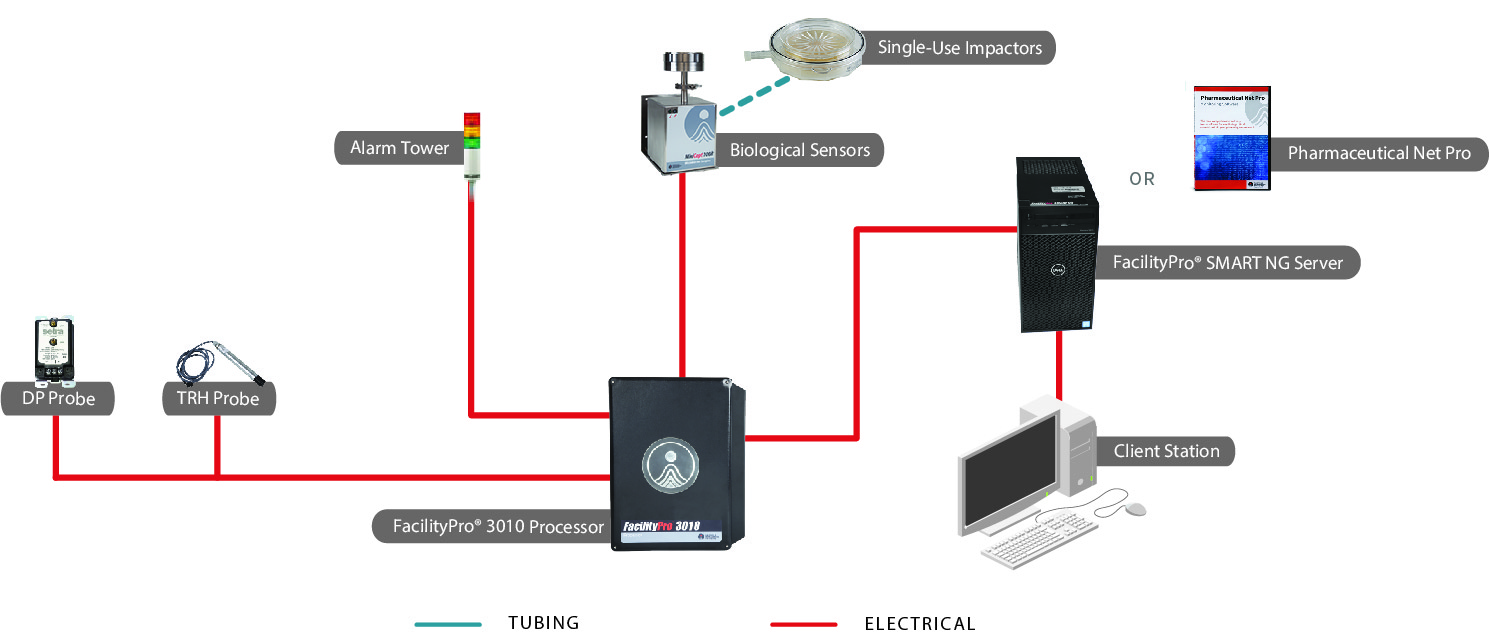

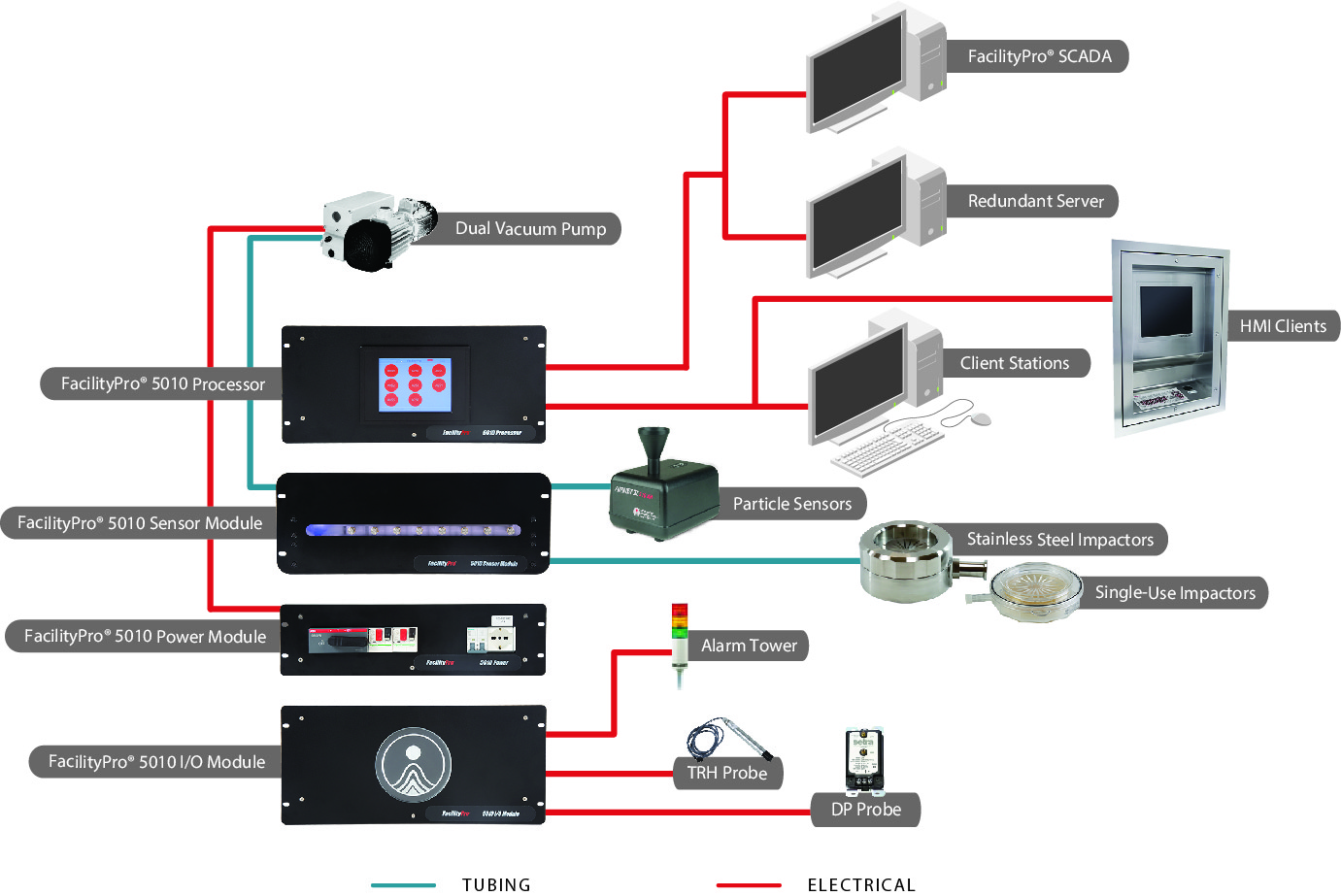

System Configuration Examples

Our modular Systems can be configured to meet your specific needs! Here are three examples, or get a more complete listing of configuration examples.

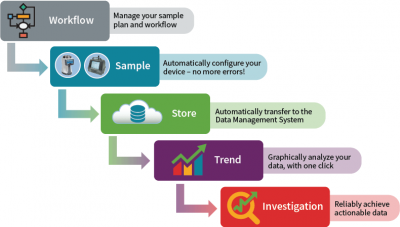

System Automation

Easily collect, report and analyze cleanroom environmental monitoring data. Request a QuoteDetection – Sensors

Viable and non viable samplers from a single manufacturer. Wide variety of analog sensors available including TRH, DAP, Air Flow velocity, etc. Digital inputs and outputs to interface with a selection of operational processes.

Viable Active Air Samplers

Non-Viable Particle Counters

Data and Process Management Software

Enhance your system integration with FacilityPro® SQL Data Exporter and OPC UA drivers to enable plug and play communication with isolator, filling line, LIMS, MES, and other data management software to support accurate decision making and compliance while assuring quick and accurate batch release.

Request a Quote

Request a Quote

Environmental Monitoring Systems

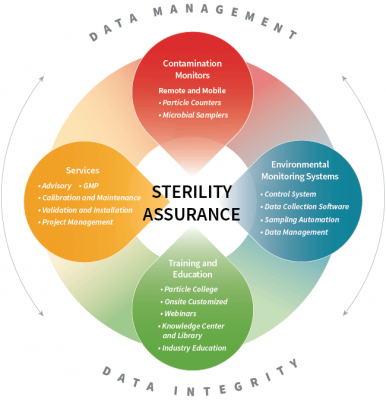

An environmental monitoring system (EMS) is used in pharmaceutical manufacturing to verify control of the aseptic processing environment and meet regulatory requirements. Particle Measuring Systems offers a variety of EMS solutions to meet different process needs.

Facility Monitoring Software

Particle Measuring Systems is the global leader in contamination monitoring solutions, providing a complete solution consisting of sensors, control systems, and data management software. Particle Measuring Systems’ solutions cover the entire lifecycle of a contamination monitoring project, from initial planning to ongoing support and training.

FMS Implementation

We work with our customers to provide the full monitoring solution from start to finish. Our advisory team can conduct the risk assessment determining when, where, and what to sample. Our project delivery team then takes over to handle the installation, commissioning, validation, and training. Finally, our global service centers will perform the routine calibrations, preventative maintenance, and repairs, all using the same standards and procedures to ensure accurate, consistent monitoring.

Argonaut Manufacturing Chooses PMS

Learn why Argonaut Manufacturing Chose Particle Measuring Systems for their cleanroom environmental monitoring, replacing the default system that was on their filling line.