Cleaning Procedure Using Floss (for S-Series Only)

Sometimes the source of contamination is aggressively attached to the surface of Particle Measuring Systems (PMS) Liquilaz S Series liquid particle counter capillary. When these rare events occur, using cleaning syringes will not be sufficiently effective to return the DC light value to acceptable limits. Under these situations, using a product called SuperFloss®, manufactured by Oral-B®, will sometimes dislodge the contamination. Follow these steps only after an unsuccessful series of attempts to clean the capillary with the syringes.

Caution: Cleaning Procedure Using Floss is NOT intended for LiQuilaz E-Series capillary cleaning.

This procedure is designed for the LiQuilaz S-Series only.

Cleaning Procedure Using Floss (for S-Series Only)

- If necessary, remove the 6 mm fittings from the LiQuilaz particle counter inlet and outlet fittings.

- Remove a single strand of SuperFloss from the package. Do not use “flavored” floss that can leave a film on the capillary instead of cleaning it.

- One end of a piece of SuperFloss is stiffened with wax, while the other end is only compressed into stiff dental floss.

Never pass the waxed end through the capillary.

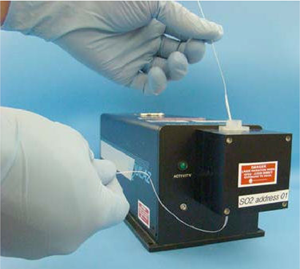

Never pass the waxed end through the capillary.- Identify the un-waxed end of the SuperFloss and insert it through the capillary.

- As the spongy section reaches the capillary, wet it lightly with the cleaning solution identified in Cleaning Solution.

- Be very careful not to spill any fluid onto the gaps between the metal sections of the LiQuilaz particle counter housing.

- Immediately wipe up any spills.

- Gently pull the wetted portion of the spongy floss back and forth through the capillary. The best technique is to pull on one end without holding onto the other end.

- Then release the side you were pulling and begin pulling from the other end. This will allow the floss to remain large and spongy as it travels through the capillary, contacting all surfaces of the capillary.

- After 10 – 15 seconds of flossing action, remove the SuperFloss from the capillary. Remember: Do not pull the waxed end through the capillary. Remove it from the same direction that it was inserted.

- Connect the LiQuilaz particle counter inlet to a source of ultra-pure deionized water.

- Connect the LiQuilaz outlet to a drain suitable for cleaning fluid.

- Flush cleaning fluid from the LiQuilaz for 3 – 5 minutes with DI water.

- Check the DC light using the software provided.

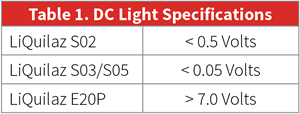

- If DC light fails to meet sensor specifications (Table 1) repeat cleaning with one additional strand of SuperFloss.

- If DC light still does not meet sensor specification, return the instrument to the Particle Measuring Systems certified service department.

Relevant Content

https://www.pmeasuring.com/blog/liquilaz-particle-counter-maintenance-cleaning-pr/

https://www.pmeasuring.com/blog/selecting-a-cleaning-solution/