Laser Life Factors

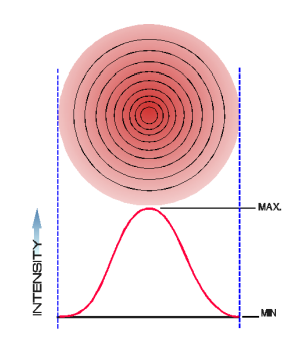

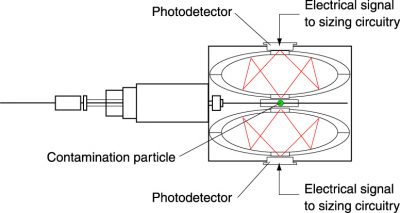

Particle counters use lasers which provide intense light to count very small particles. All lasers have a finite lifetime, but that lifetime can be extended or shortened based on how the laser is used. Your cost of ownership will decrease if the laser lasts longer. Particle Measuring Systems was the first company to build a laser-based particle counter, and we have the best understanding of how to extend laser life.

The three major factors that determine laser life are:

The three major factors that determine laser life are:

- the design and manufacture of the laser itself

- the operating temperature of the laser

- the operating power that is used versus the rated power of the device

The first step in providing a particle counter with long laser life is to start with a reliable laser. The lasers used are not designed specifically for particle counters, but instead are designed for other devices. Previously Particle Measuring Systems used lasers intended for CD drives; these lasers typically operated at wavelengths of 780 nm. However, as CD-only players became less common, so did these lasers. Be wary of buying a device currently using 780 nm lasers: there is a strong possibility that the device will be discontinued in the near future, and servicing the instrument will be expensive and difficult, if not impossible.

Particle counters use lasers that provide sufficient wavelength and energy levels to meet particle sizing specifications. These lasers typically have wavelengths in the 630-680 nm range. Particle Measuring Systems also uses high-powered lasers that operate at or near 808 nm for our high sensitivity instruments. These lasers are much more expensive than DVD lasers, often costing several thousand dollars. However, as this wavelength is a “preferred” wavelength of GaAs (the lasing material), it simplifies the manufacturing process, saving some production and maintenance costs. Both the 630-680 nm and 808 nm lasers are very reliable because they are presently manufactured regularly, and they are used for a number of applications that require high power. Their demand confirms their staying power in the market, assuring their availability and serviceability.

The second factor that drives laser lifetime is the operating temperature of the laser. Higher temperatures reduce laser life. Our rule of thumb is that laser life is halved for every 8ºC increase in temperature. During operation, the lasers generate heat which must be dissipated effectively, or the temperature of the diode will increase and shorten its lifetime. Particle Measuring Systems carefully designs our laser systems and laser mounts to minimize laser operating temperatures. In the case of the high-powered lasers, the laser chip is mounted directly onto a thermo-electric cooler (TEC) which allows us to precisely control the temperature, thus extending laser life.

The second factor that drives laser lifetime is the operating temperature of the laser. Higher temperatures reduce laser life. Our rule of thumb is that laser life is halved for every 8ºC increase in temperature. During operation, the lasers generate heat which must be dissipated effectively, or the temperature of the diode will increase and shorten its lifetime. Particle Measuring Systems carefully designs our laser systems and laser mounts to minimize laser operating temperatures. In the case of the high-powered lasers, the laser chip is mounted directly onto a thermo-electric cooler (TEC) which allows us to precisely control the temperature, thus extending laser life.

The third factor…

Learn more… Complete the form to Download the paper.