Particle counters are used in many applications ranging from cleanroom and clean air device classification in accordance with specified standards, testing of filter installation, portable environmental monitoring programs, in-situ environmental monitoring systems and the fault diagnosis of specific processes. Historically, there has been a single volume flow rate of 1 CFM (28.3 LPM) chosen for many of these applications.

Manufacturers of particle counters found that as regulations changed, higher volume flow rates were preferred for the classification of cleanrooms to either ISO14644-1(1) or EU GMP Annex 1(2) standards.

Particle Measuring Systems originally led the market with a true 100 LPM instrument, which enabled faster sampling of the cubic meter of air required for classification of a cleanroom either to ISO 4 or cleaner, or an EU GMP Grade A aseptic zone. The requirement for monitoring a process using a ‘standard’ 1 CFM device however, continues to prove the most suitable method of acquiring data at an ideal rate and with confidence that the process can be economically measured.

Particle Counter Types

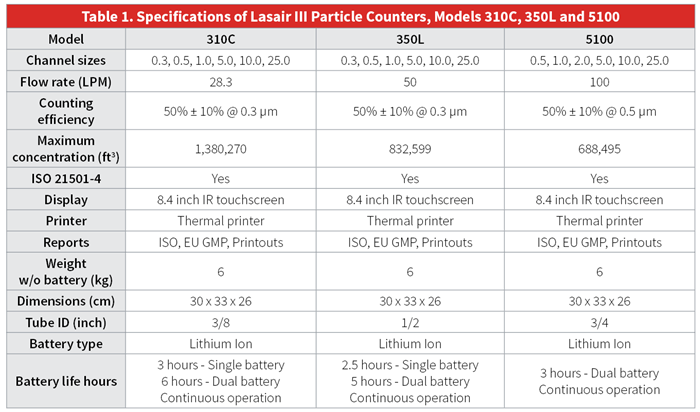

Three instruments available from Particle Measuring Systems that satisfy all current needs of room classification and environmental monitoring programs are described in the table below.

As there are different types of instruments available, each with a different flow rate, a concern arises in the industry of what constitutes suitable transit of particles within tubing. Particle Measuring Systems has previously released information regarding the maximum suitable length of transport tubing(3) and this has been reinforced by the release of ISO 14644-1:2015 which advocates for shorter tubing lengths(1), World Health Organization requirements for vaccine manufacture which recommends that no more than 2.0 meters of tubing should be used(4), and the upcoming release of the updated EU GMP Annex 1, which discusses particle counter applications.

The next installment will discuss turbulence and how the Reynolds number can provide a basis for comparing tubing flow rates. To download the full paper, click here.

- ISO 14644-1, Cleanrooms and associated controlled environments – Part 1: Classification of air Cleanliness, 2015.

- EU Guidelines to Good Manufacturing Practice, Medicinal Products for Human and Veterinary Use, Annex 1 – Manufacture of Sterile Medicinal Product, 2008.

- An Analysis of Acceptable Particle Losses in Transport Tubing, PMS Application Note 81 (2007).

- Environmental Monitoring of Cleanrooms in Vaccine Manufacturing Facilities, World Health Organization, Final Draft March, 2010.

- J P Holman, Heat Transfer, McGraw-Hill, 2002, p 207.

- ISO 21501-4 Determination of particle size distribution, single particle light interaction methods – Light scattering airborne particle counter for clean spaces, 2007.