The key to a successful project around Planning and Installing an Environmental Monitoring System is to ensure that all phases of the implementation are executed in a timely manner. The identification of each of the major steps can be presented as a GANTT chart, which will also identify when obstacles, such as shutdowns, need to be accommodated. Figure 2 shows a typical timeline GANTT chart for a complete project.

Each of these summary tasks can be broken down into individual tasks so that resources, both material, and labor, are available. This becomes more critical when multiple components of a project are encroaching on each other. This often occurs during installation when different trades are vying for the same space and during validation when deadlines are tight.

Environmental Monitoring System Design

There are several documents (see references list below) that identify how best to design a particle monitoring system. Considerations include a selection of sample points, which hardware to use for each application, and the relationship between risk versus instrumentation.

Any changes required to a system that makes it user-friendly should be incorporated as early in the project as possible to avoid costly changes to the later task of building the system and overall project scope.

Environmental Monitoring System Installation

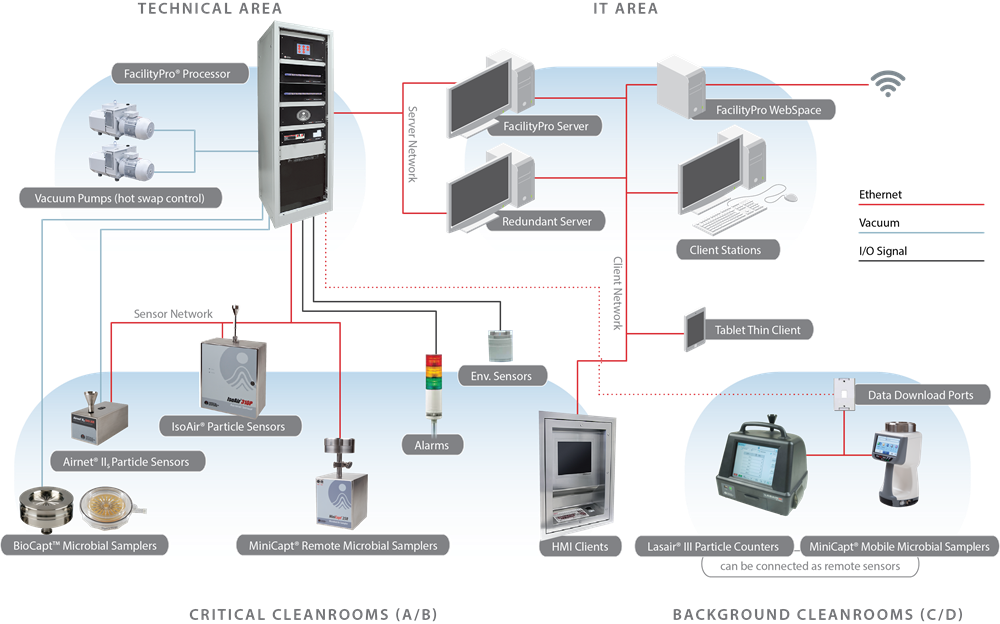

The main components to be installed for a monitoring system are wiring, tubing, sensors, data cabinets and vacuum pumps, and computing and network infrastructure. This is summarized in the following image:

Environmental Monitoring System Validation and Testing

The validation of the installed system follows the GAMP Guide, which continues from the initial URS and the design documents. A matrix of key components identified in the URS links to suitable tests to prove the robustness of the system. Validation of the system typically takes anywhere from a few days to a few weeks depending on the size and complexity of the design.

Environmental Monitoring System Implementation and Training

This final stage causes the most concern with many new users of systems as the volume of data generated is much greater than that historically generated using a portable solution. The data can no longer be seen as a single page of data. A single particle counter can generate 5 -10 pages of data per day, if this is extrapolated to a 10 sensor system, 50 -100 pages can be reported – an ever-increasing volume of data that is handled with proper user training.

Learn more… Get the full paper.

References

- EC Guide to Good Manufacturing Practice, Revision to ANNEX 1, European Commission, Enterprise Directorate General, February 2008.

- GAMP 5 Guide: Compliant GxP Computerized Systems; February 2008, published by the ISPE.

- Choosing the most suitable non-viable sample point locations, Technical Note 79, M Hallworth, Particle Measuring Systems 2007.

- Particle monitoring requirements in Pharmaceutical Cleanrooms, Application Note 41, M Hallworth, Particle Measuring Systems 2005.

- An Analysis of Acceptable Particle Losses in Tubing, Application Note 81, M Hallworth, Particle Measuring Systems 2010.