Establishing and maintaining cleanroom performance of aerosol particles in a cleanroom often requires the use of multiple particle counters with varying design parameters and display settings. Commonly, cleanroom personnel employ the use of multiple optical particle counters (as defined in ISO 14644-1) to report an array of airborne particle counts. This paper is a summary of the basic methods cleanroom personnel may use to ensure that the data that is reported by different aerosol particle counters can be compared effectively. This is accomplished by making sure differences are understood and appropriate data conversions can be made to make meaningful comparisons. OPCs for Statistical Process Control (SPC) is outlined along with how SPC statistical rules are applied when using metrology instruments to establish and maintain process control in airborne particle counts of a cleanroom, even with the use of different instruments.

Specific detail with regards to instrument-to-instrument variability can be found in the companion paper, A Practical Guide to Aerosol Particle Counter Matching, and is recommended to be utilized in conjunction with this document.

Overview

The document covers:

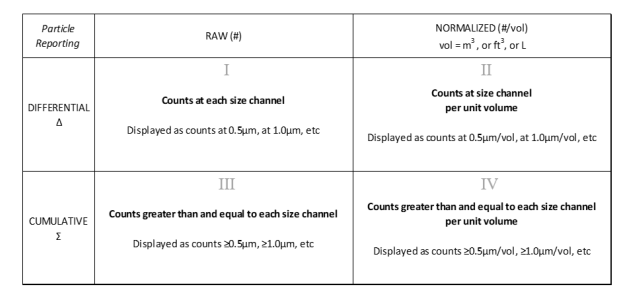

- Differences between Raw-Differential (I), Normalized – Differential (II), Raw-Cumulative (III), and Normalized-Cumulative (IV)

- Explanation of conversions between particle count methods

- Isoaxial and Isokinetic Sampling in Laminar Flow

- Tubing and Particle Transport

- Counters used in Characterization, Certification, and Ongoing SPC

Converting Raw Counts (I and III) to Normalized Counts (II and IV)

When raw counts are reported and the volumetric flowrate is different between particle counters, the raw counts must be converted to normalized counts by dividing the displayed raw counts by the total volume of air collected during the sample. This is done by dividing the raw counts by the product of the sample flowrate multiplied by the sample collection time. See below.

Normalized Counts (#/vol) = Raw Counts / [Sample Time (Time) X Volumetric Flowrate Volume/Time)]

For example, if a counter, labelled “A”, with a 1 ft3 /min volumetric flowrate is used with a 1-minute sample collection interval, and is then compared to another counter, labelled “B”, with a 0.1 ft3 /min flowrate with a 5-min sample time, then the raw counts must be divided by time multiplied by flowrate:

▷ Counter A normalized = Raw Counts # / [1 min X 1 ft3 /min] = Counts # / ft3

▷ Counter B normalized = Raw Counts # / [5 min x 0.1 ft3 /min] = Counts # / ft3

In this example, the units of the result are the number of counts per cubic foot, which can be converted to counts per liter by multiplying the result by a conversion factor of 1 ft3 / 28.32 L, or 0.035 ft3 /L.

▷ Counts # / ft3 x [0.035 ft3 /L] = Counts # / L

Aerosol particle characterization, certification, control, and sustaining within the cleanroom requires high-performance particle counters that are stable and well-matched as defined by ISO 14644 and ISO 21501-4 standards. There will always be differences between particle counters, and the sources of potential differences should be understood and minimized. However, as long as the counters are able to perform to high-quality standards, powerful SPC rules can be used to establish and maintain control even with marginal differences between counters.